While waiting for a ZN part (more on that later), it seemed like a real good time to put the cylinder head back together. To get started, all that needs to be done is remove the four camshaft caps. However, nothing ever is easy. Is it?

After removing three of the four caps, the second to last bolt on the fourth cap just snapped in half. The screw didn’t feel stuck when taking it off. There was no ‘struggle’ of any kind. Simply went “snap!”

Anyone who’s spent time twisting screwdrivers, wrenches or ratchets has had to deal with stuck and broken fasteners. Because it happens a lot when working with old bikes, I made a list of ways to deal with the situation. It’s not actually a flow chart but I’ll start with the first option if I can then work my way down the list.

- Impact Driver with some lapping compound.

- Use a Dremel to cut a line into the head. Use a flat head screwdriver to remove it.

- Use a small chisel to gouge and hammer the screw counter-clockwise. Use a Dremel to grind a flat on the periphery of the screw head, and then use a hammer and chisel on the flat to turn the screw.

- Heat the metal around the screw. Use needle-nose vice grips to twist it out.

- Grind off the head of the bolt. If there’s a cover, remove it so the shaft is exposed. Use needle-nose vice grips on the shaft to remove it.

- Drill into the screw just far enough to break the head off the shaft. Do this with each screw head that is rounded and remove the cover that the screw is holding on. Now the shaft of the screw is sticking out so grab it with a vice grip and unscrew it.

- Soak in penetrating oil overnight then try the vice grip again. Don’t go nuts with it. Don’t twist off the exposed part of the screw.

- Heat up the area around the bolt to about 212 degrees or cherry red. Let it cool or even better help it cool with ice. Don’t go nuts with it and don’t melt the aluminum. Try the vice grip again.

- Heat and cool and oil and vice grip the part over and over again. Worry it out!

- If the shaft is really in there and won’t come out or if it broke off level with the case, use a center punch to put a deep dimple in the center of the shaft to help start a drill. Now, drill a small hole into the shaft. Start small and then go to the next size larger bit. As soon as there’s a big enough hole, try to use an easy-out. Don’t go nuts with it. Turn the tool gently.

- If it still won’t come out, then keep drilling and going up one size at a time until hitting the threads. Then use a pick or needle and peel the threads of the screw out from the threads of the case. If the case threads get buggered up, put in new threads with a Helicoil.

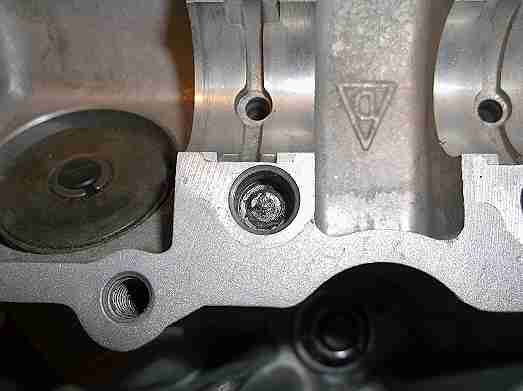

Because this screw wasn’t really stuck, it should have easily come out except…it’s recessed down into a well.

Also, both the screw and the well are narrow, making it impossible to reach with the smallest of needle-nose pliers or hemostats.

A technique from above that always works for me is #2. Of course, here the Dremel cutting wheel wouldn’t reach, but there was an extremely small engraving cutter in my Dremel stash. The cutter did well enough to make a slight line into the screw’s shaft.

Luckily, I recently bought two new screwdrivers: a Lenox Tools 23932 Multi-Tool Driver and a Bessel. These aren’t high end tools, but they aren’t junk either. What they are, however, is good enough and new enough to offer a nice sharp edge that’ll grab hold of the slightest indent.

In addition, judicious use of PB Blaster and jeweler’s pliers helped get the job done. I originally thought the head might have to go to the machine shop. Fortunately, I developed enough patience by working on these bikes so that I know how to worry the heck out of this broken bolt.

Next: The dark art of bobber electrics